URC-25

Basic information

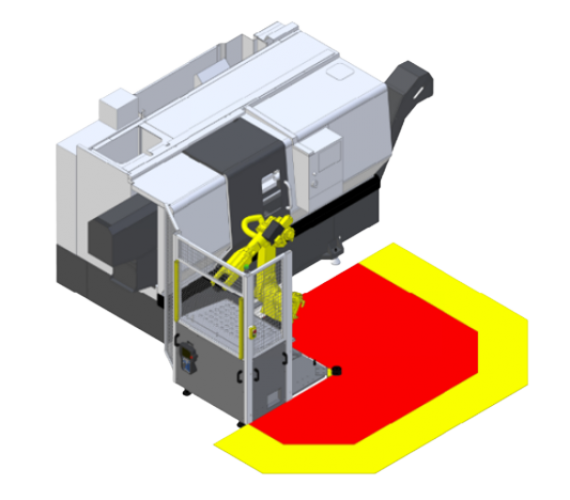

Teximp Universal Robot Cell is an all inclusive robotic automation solution for your Haas machine. The URC-25 is based on Fanuc M-20iD/25 robot arm suitale for bigger size machines.

Robot hand description

Fanuc robot M20iD/25

- 6-axis vertical robot

- Load capacity 25 kg / reach 1813mm

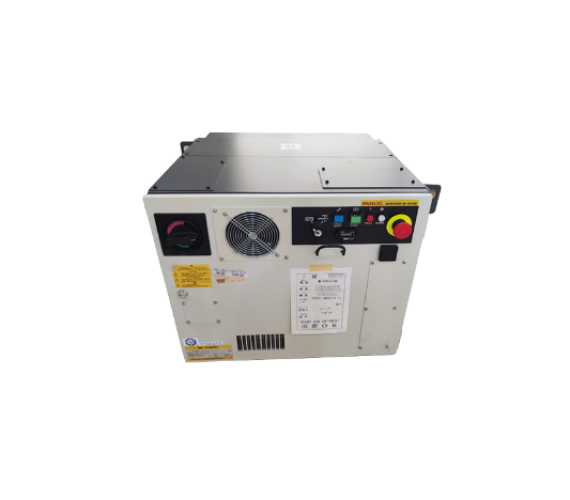

- A plus cabinet

- I/O modules; DI16 / DO16

- DCS Dual Check Safety Position (J567)

- Soft Float (J612)

- Touch Skip (J921)

- Singularity Avoidance (R792)

- User Socket Messaging (R648)

- Karel (R632)

Part Table

Compact but heavy part table with front entrance.

- Table size 980 x 700mm

- Three pins for quick pallet changing

- Omron safety light curtain, cat.4

- Control button 3

- LED status beacon

- Electrical cabinet and cables

Includes Safety Option

The Cage is our standard solution. All URC cells can also be delivered in the "Laser" version, which is designed for optimal accessibility. The price of the cells remains the same regardless of the chosen version.

-

Cage (Standard)

-

Omron Laser (Alternative)

-

Omron Light Curtain (Standard)

Standard Color

Choose from our two recommended colors at no additional cost.

Any other colors are available upon request, with a potential delivery time increase of up to 10 weeks.

-

RAL 7035 (Standard)

-

RAL 1018 (Alternative)

Included Interface to the Haas machines

Teximp Robot Interface includes all needed to connect the URC to any Haas machine. Support Haas Mill and Lathe machines, with NGC and CHC control.

- Communication CNC <=> URC, I/O, M-fin, safety

- Preparing for a Clamping device

(2nd clamping device available) - Preparing for a PAD

- Preparing for an external Air Blow

Gripper Configuration

The Teximp Gripper Interface includes everything needed for clamping parts on the robot side.

- Gripper carrier 90°

- Schunk Gripper JGP-P 100-2 (2 pcs)

Stroke per jaw [mm] = 5

Recommended workpiece weight [kg] = 8.75 - ABR-PGZN-plus 100 blanks made of aluminum for rework by the customer

- Sensors G1/G2 - clamped/unclamped

- Blower nozzle

Other possibility:

- Gripper carrier 180°

- Schunk Gripper JGZ 100-1 (2 pcs)

Stroke per jaw [mm] = 10

Recommended workpiece weight [kg] = 9 - Sensors G1/G2 - clamped/unclamped (4 pcs)

- Blower nozzle

Depending on the required gripping technology, many other types of the TGI are available. For more details, please refer to the ACCESSORIES section.

Included Auto Door

Our robot cell includes an Auto Door for any Haas machine, with two available solutions: the original Haas Smart CAN DC Auto Door for machines built in 2020 and later, or Teximp’s Pneumatic Auto Door for older machines.

- PAD-HaasVF-side

- PAD-HaasVF-front

- PAD-HaasMM-front

- PAD-HaasST

- PAD-HaasUMC

PADs for machines without the original side door/window are also available. For more details, please refer to the ACCESSORIES section.

Programming Option

The Visual Programming Dialog (VPD-HMI) enables intuitive interaction with Teximp robotic systems through a visual interface, facilitating configuration, monitoring, and optimization of operations. It allows operators to program quickly and easily, without the need for Fanuc programming knowledge. Our engineers can prepare a job list, enabling a complete setup change with just one parameter adjustment. This simplifies the programming process and minimizes downtime.

-

Easy visual programming

-

No additional hardware required