Custom

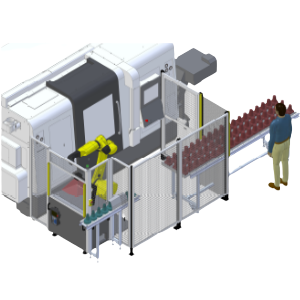

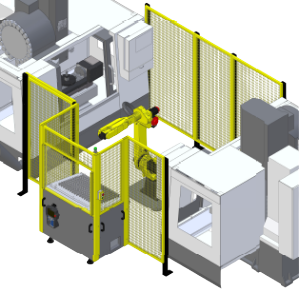

Multiple machines

A robotic cell serving multiple machines enhances efficiency, especially for processes with long cutting times. It can manage up to three machines with a single robot, streamlining operations and optimizing workflow.

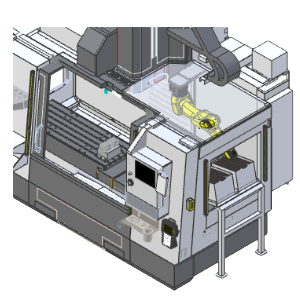

Integrated robot

For optimized cycle times, an integrated robot is recommended, as it eliminates delays caused by slower automatic door systems. The robot is mounted directly within the CNC machine enclosure, enabling synchronized motion control and direct access to the work area.

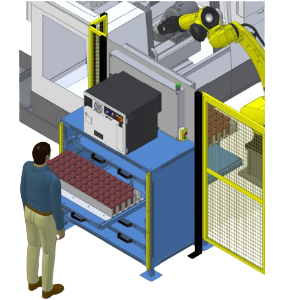

Drawer system

The drawer system provides extended autonomy by allowing continuous operation with minimal operator intervention. While the robot is working with one drawer (or cartridge), the next batch of raw parts can be safely loaded or unloaded in the other—ensuring uninterrupted workflow and maximizing machine uptime.

Conveyor system

The conveyor system enables the transfer of semi-finished parts to secondary stations for additional operations such as measurement, final machining, or packaging. This ensures a smooth and automated workflow between production stages, increasing efficiency and reducing manual handling.