URC-35P

Basic information

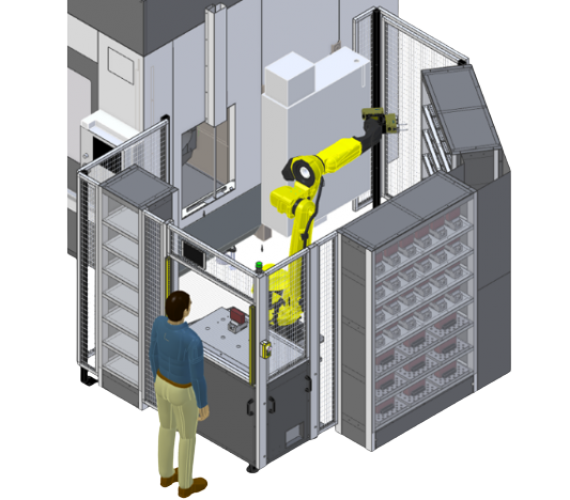

Teximp Universal Robot Cell is an all inclusive robotic automation solution for your Haas machine. The URC-35P is based on Fanuc M-20iD/35 robot arm addapted for handling pallets or vises.

Robot hand description

Fanuc robot M20iD/35

- 6-axis vertical robot

- Load capacity 35 kg / reach 1813mm

- A plus cabinet

- I/O modules; DI16 / DO16

- DCS Dual Check Safety Position (J567)

- Soft Float (J612)

- Touch Skip (J921)

- Singularity Avoidance (R792)

- User Socket Messaging (R648)

- Karel (R632)

Loader Table

Compact but heavy loader table with front entrance.

- Table size: 980 x 700 mm

- Docking station with four pockets

- Three locating pins for quick pallet exchange

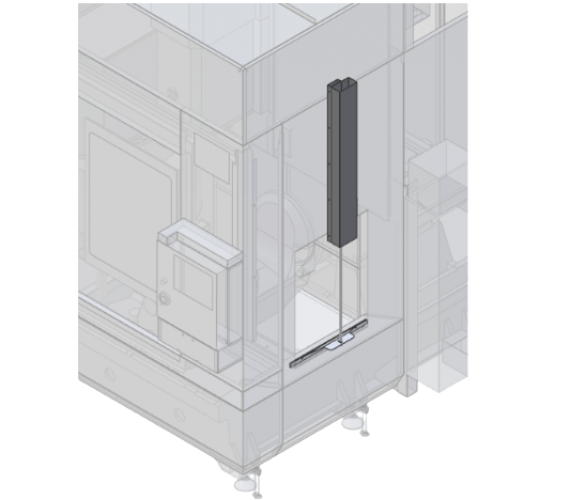

- OMRON safety light curtain, Cat. 4

- Three control buttons

- LED status beacon

- Electrical cabinet and cables included

Pallet Rack

The URC-35 Palletizing cell is equipped with one large-capacity rack with 42 pockets. The system can be extended with a second large rack and one slim cabinet for increased storage flexibility.

- Large rack (42 pockets) - included as standard

- Second large rack (42 pockets) - optional

For storing additional pallets or special tools - Slim cabinet (14 pockets) - optional

For additional pallet storage or automatic gripper exchange

Pallet type

The URC-35P robotic cell is designed to automate the handling of both workholding pallets and precision vices, offering exceptional versatility for various machining applications.

The system is delivered with:

-

5 BIANCO aluminum pallets – size 160 × 170 mm, lightweight and robust

-

5 Lang Makro•Grip 77 vices – 5-axis vices with 77 mm jaw width and clamping range 0–120 mm

Vices are mounted on a RoboTrex 52 pneumatic zero-point clamping system, allowing precise, repeatable and automated positioning of workpieces without manual setup. The remaining rack pockets can be populated with additional pallets, vices, or other workholding elements depending on your process requirements.

Supported Pallet Sizes:

-

160 × 170 × 30 mm (Aluminum / 2.0 kg)

-

320 × 230 × 30 mm (Aluminum / 4.0 kg)

-

160 × 340 × 30 mm (Aluminum / 5.7 kg)

Pallet Types:

-

Threaded – pre-drilled and tapped holes for direct fixture mounting

-

T-slot – for flexible positioning of clamps and stops

-

Bianco-style – compatible with standard Bianco clamping accessories

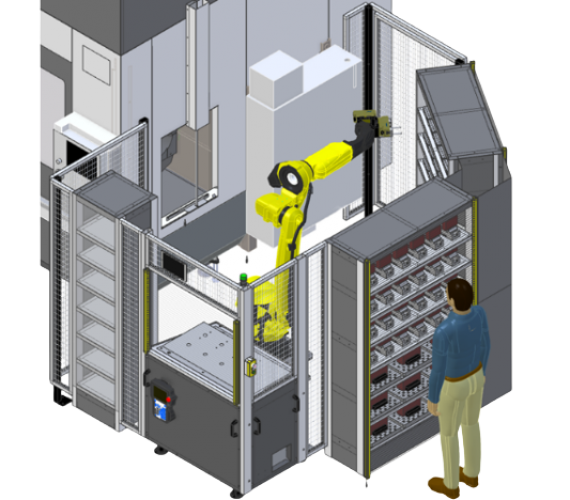

Includes Safety Option

Loading of pallets or vices onto the rack can be performed by the robot from the URC part table. However, direct manual access is also possible and supported.

- Plexiglass cover included as standard

- Omron safety light curtain available on request

- Partial entry safety cabinet available on request

Included Interface to the Haas machines

Teximp Robot Interface includes all needed to connect the URC to any Haas machine. Support Haas Mill machines, with NGC and CHC control.

- Communication CNC <=> URC, I/O, M-fin, safety

- Preparing for a Clamping device

(2nd clamping device available) - Preparing for a PAD

- Preparing for an external Air Blow

Gripper Configuration

Teximp Gripper Interface includes all needed for clamping pallet or vice on robot side.

- Gripper carrier 90°

- Schunk Gripper JGP-P 160-2 (2pcs)

Stroke per jaw [mm] = 8

Recommended workpiece weight [kg] = 24.5 - Preparation for vice/pallet clamping

- Sensors G1/G2 - clamped/unclamped

- Blower nozzle

Included Auto Door

URC-35 Palletizing can be equipped with a pneumatic autodoor (PAD) for selected Haas machines. Available PAD models include:

- PAD-HaasUMC-side

- PAD-HaasVF-side

Programming Option

The Visual Programming Dialog (VPD-HMI) provides an intuitive interface for seamless interaction with Teximp robotic systems. It simplifies configuration, monitoring, and operation optimization by allowing users to create and manage programs visually—without requiring prior knowledge of FANUC programming.

Teximp engineers can predefine job lists, enabling complete setup changes with a single parameter adjustment. This significantly streamlines the programming process and reduces machine downtime.

-

Easy and intuitive visual programming

-

No additional hardware required